Introduction: In the world of electrical connections, the integrity of joints is paramount for safety, reliability, and efficiency. Exothermic welding, a process that uses the heat generated by a chemical reaction to create robust connections, has emerged as a preferred method for achieving durable and long-lasting bonds in diverse applications. This article explores the intricacies of exothermic welding, its benefits, and its applications in various industries.

Understanding Exothermic Welding: Exothermic welding, also known as exothermic bonding or thermite welding, is a process that involves the controlled chemical reaction between a powdered metal oxide and a reducing agent. This reaction generates intense heat, melting the metals and allowing them to fuse into a molten pool. Upon solidification, a solid, high-quality weld is formed.

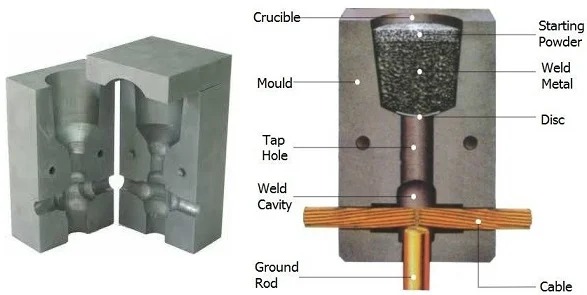

Key Components of the Exothermic Welding Process:

Mold or Graphite Crucible: The mold or crucible holds the conductors in place during the welding process. Made of graphite to withstand the high temperatures generated during the reaction.

Welding Powder: A mixture of powdered metals, usually copper oxide and aluminum, that initiates the exothermic reaction. The selection of welding powder depends on the specific application and materials being joined.

Ignition Source: A spark or electric igniter initiates the chemical reaction, triggering the exothermic welding process.

Benefits of Exothermic Welding:

Superior Electrical Conductivity: Creates low-resistance connections, ensuring efficient electrical conductivity.

Durability and Longevity: Produces robust, durable welds that withstand environmental conditions and resist corrosion.

Versatility: Suitable for various materials, including copper, aluminum, steel, and other metals commonly used in electrical applications.

Consistency: Provides uniform and consistent welds, minimizing the risk of weak points in the joint.

Low Maintenance: Once the weld is made, it requires minimal maintenance, contributing to a reliable and low-maintenance electrical infrastructure.

Applications of Exothermic Welding:

Electrical Grounding: Used for grounding applications, creating secure connections between grounding conductors and grounding electrodes.

Railway Signaling: Employed in railway signaling systems to establish robust connections for signal bonds and rail joints.

Telecommunications: Utilized for creating reliable connections in telecommunications infrastructure, including tower grounding and lightning protection systems.

Industrial and Utility Installations: Widely adopted in industrial settings for welding large conductors, such as those found in power distribution and substation applications.

Conclusion: Exothermic welding has proven itself as a reliable and efficient method for creating enduring electrical connections. Its widespread use in various industries attests to its effectiveness in achieving durable joints that contribute to the safety, efficiency, and longevity of electrical systems. As technology continues to advance, exothermic welding remains a cornerstone in the foundation of secure and enduring electrical infrastructure.